• Faster crystal growth speed - 10-100 times faster than traditional methods

• More production capacity - more production capacity in a single batch

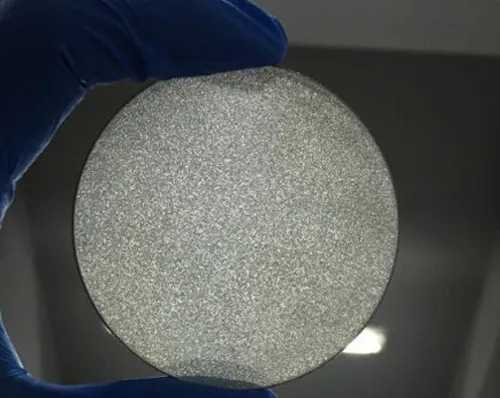

• Higher quality performance - higher hardness and toughness than natural diamonds.

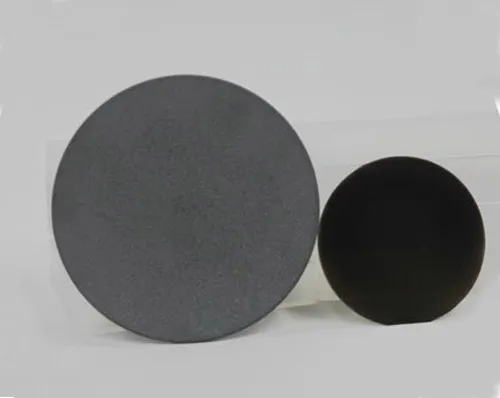

• More diversified colors - white, yellow, pink, blue, etc.

• Higher diamond purity - purer than natural diamond Type II

• Multi style customization can be customized according to different market

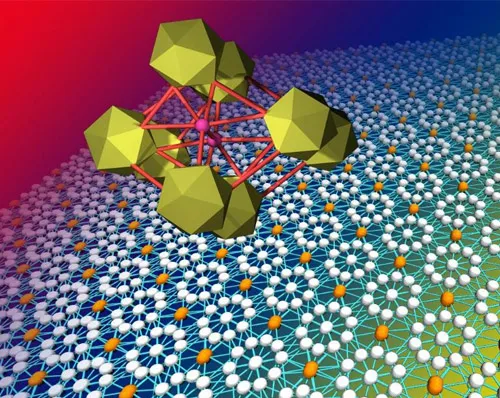

Microwave plasma chemical vapor deposition (MPCVD) is the mainstream equipment for diamond growth. The gas sources used by MPCVD equipment mainly include hydrogen (H2), methane (CH4), nitrogen (N2) and oxygen (O2), which are cracked into H, O, N atoms or CH2, CH3, C2H2, OH and other groups under the action of microwave. Carbon containing groups (CH2, CH3, C2H2) will form gas-solid mixed interface on the diamond surface, and diamond (sp3), amorphous carbon or graphite (sp2) can be grown under the dynamic equilibrium model or non-equilibrium thermodynamic model. The etching speed of amorphous carbon or graphite (sp2) by hydrogen plasma is much faster than that of diamond (sp3), so the non diamond phase on the surface of CVD diamond is rapidly etched to achieve diamond growth.

Microwave plasma chemical vapor deposition (MPCVD) is the mainstream equipment for diamond growth. The gas sources used by MPCVD equipment mainly include hydrogen (H2), methane (CH4), nitrogen (N2) and oxygen (O2), which are cracked into H, O, N atoms or CH2, CH3, C2H2, OH and other groups under the action of microwave. Carbon containing groups (CH2, CH3, C2H2) will form gas-solid mixed interface on the diamond surface, and diamond (sp3), amorphous carbon or graphite (sp2) can be grown under the dynamic equilibrium model or non-equilibrium thermodynamic model. The etching speed of amorphous carbon or graphite (sp2) by hydrogen plasma is much faster than that of diamond (sp3), so the non diamond phase on the surface of CVD diamond is rapidly etched to achieve diamond growth.

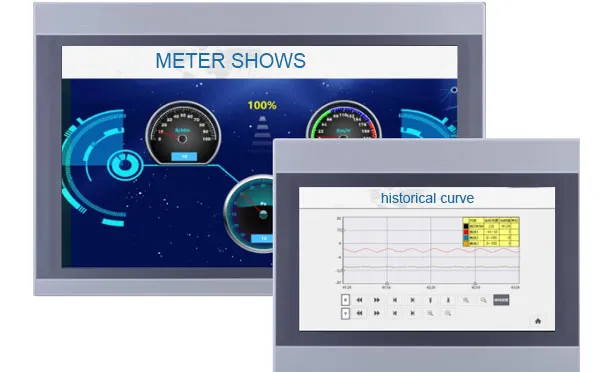

The basic structure of MPCVD equipment includes control unit, microwave unit, water cooling unit, vacuum unit, etc. The cavity is vacuumized through a vacuum unit to ensure the low vacuum state required for diamond growth. Then the control unit controls the flow rate and chamber pressure of each gas path, and leads the reaction gas source (CH4, H2, Ar, O2, N2, etc.) into the chamber and controls it at a certain chamber pressure. After the air flow is stabilized, microwave is generated through the microwave unit and guided into the cavity by the wave guide. Under the action of microwave field, the reaction gas is changed into plasma state to form a plasma ball suspended above the diamond substrate, and the substrate is heated to a certain temperature by using the high temperature of the plasma. The excess heat generated in the cavity is transmitted by the water cooling unit. In the MPCVD growth process of single crystal diamond, the optimal growth conditions are ensured by adjusting the power, gas source composition, cavity pressure and other conditions. In addition, due to the non contact between the plasma ball and the cavity wall, it ensures that there is no impurity particles in the diamond growth process and improves the diamond quality.

| Microwave Power | 6-15Kw/ 2150MHz/915MHz |

| Reactor Chamber Material | Stainless Steel |

| Stage Type | Water-cooling |

| Standard Substrate Holder | 50-120mm/2-4inches |

| tandard Gas Channel (up to 6 channels) |

3 channels (H2/CH4/N2) |

| Operating Pressure Range | 10~200 torr |

| Vacuum Leak Integrity (by He leak delector) |

< 1x10-9 mbar. l/sec |

| Vacuum Pump Type (Standard) | Rotary Vacuum Pump [18/22 m3/h (50/60Hz)] |

Heat sink

Optics

Wear-resistant device

Semiconductor

Jewelry

Precision Cutting Tools

Acoustics

Medicine

There are many statements about the growth time of lab-grown diamonds, such as one carat of lab-grown diamonds can be grown in a week, which means that they can be produced rapidly and in large quantities. Is this the case? Let have a look today!

Lab grown diamonds is a real diamond in every aspect. Its chemical, physical, atomic, optical and all characteristics are the same as those of natural diamonds.

At present, there are two kinds of machines that can make diamonds; Hexahedral press and MPCVD equipment.

there is a difference between natural and synthetic diamonds,they are indistinguishable by humans alone. Even experienced jewelers cannot tell them apart. The only way to identify them is through large-scale laboratory instruments.

Cloces

Get the latest price